In order to save a lot of foam when cutting high angle swept back wings it really helps to rotate the wing when cutting.

It also make it possible to cut high angle swept back wings wings on smaller machines.

Also check out this page by Keith Howlette that explains it in more detail:https://rckeith.co.uk/how-to-cut-large-swept-back-wings-and-save-foam/

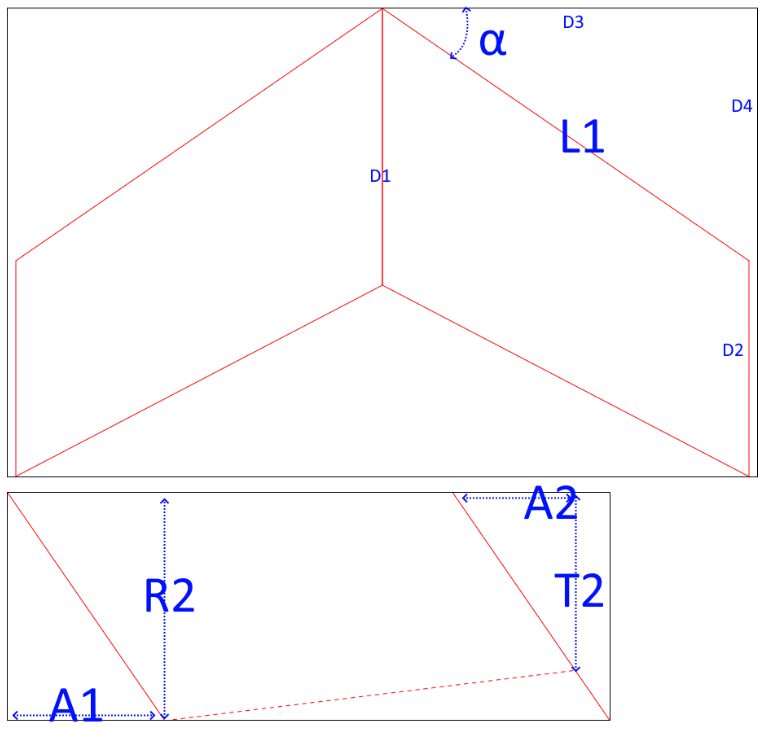

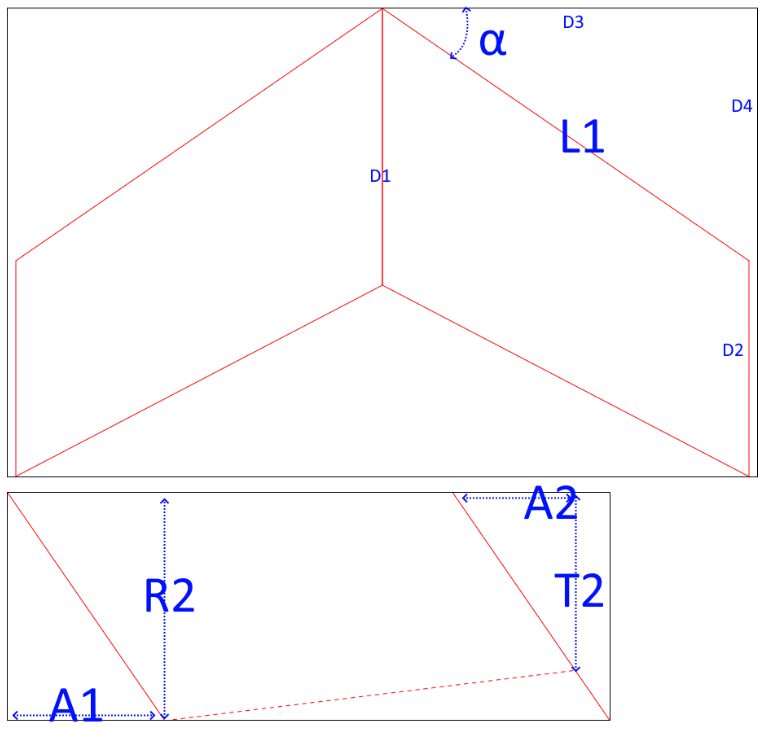

Input are the measurements D1-D4

Output are the new root, leading edge(segment) and tip lengths. And the angle to pre-cut the foam.

You can then enter all the values in the awesome "Free RC wing designer" https://www.diyrcwings.com/app/

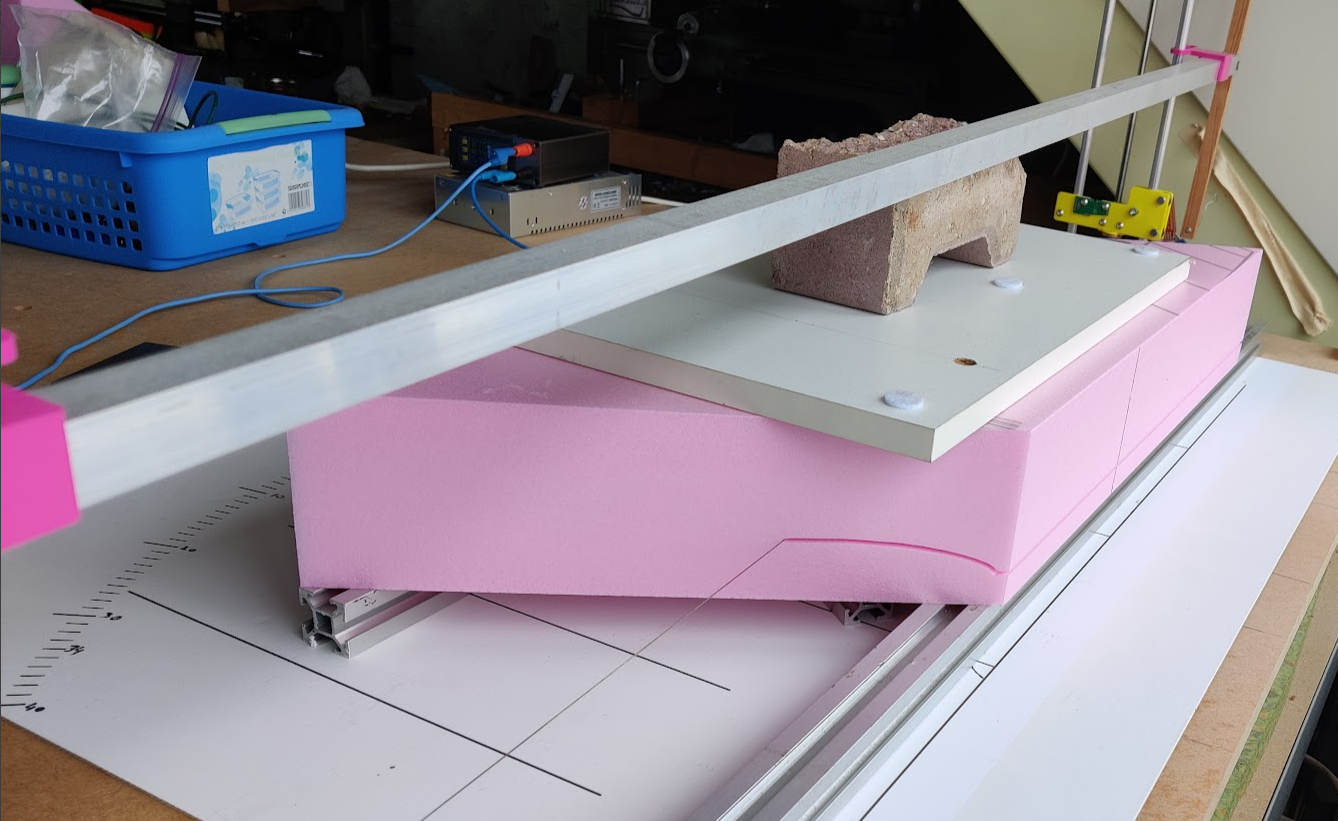

The value "Block center for cutting" should be measured from the root and marked on the foam (after cutting the angles).

This point should be on the center of your hotwire.

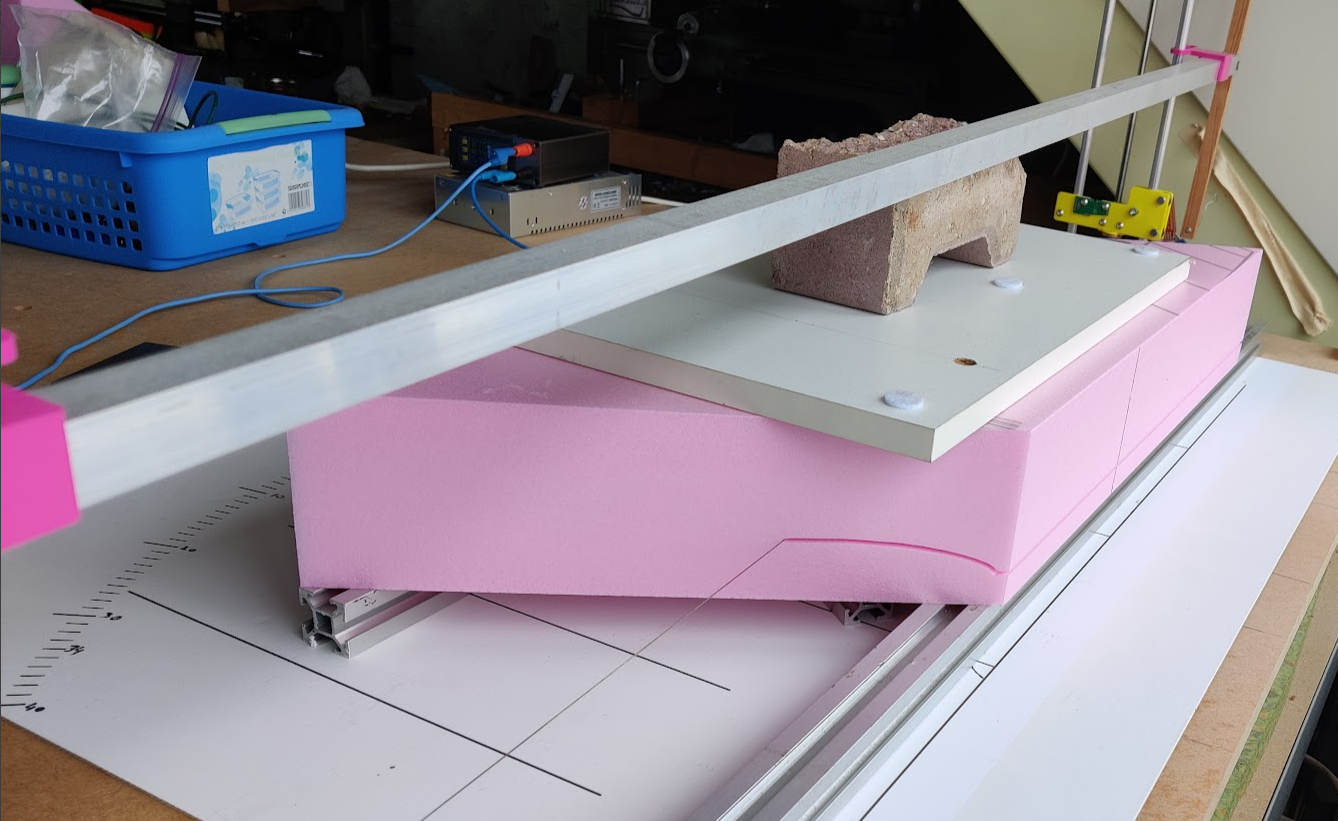

After cutting one wing just rotate the block and put the center mark back on the center of the hotwire and cut the 2nd wing.

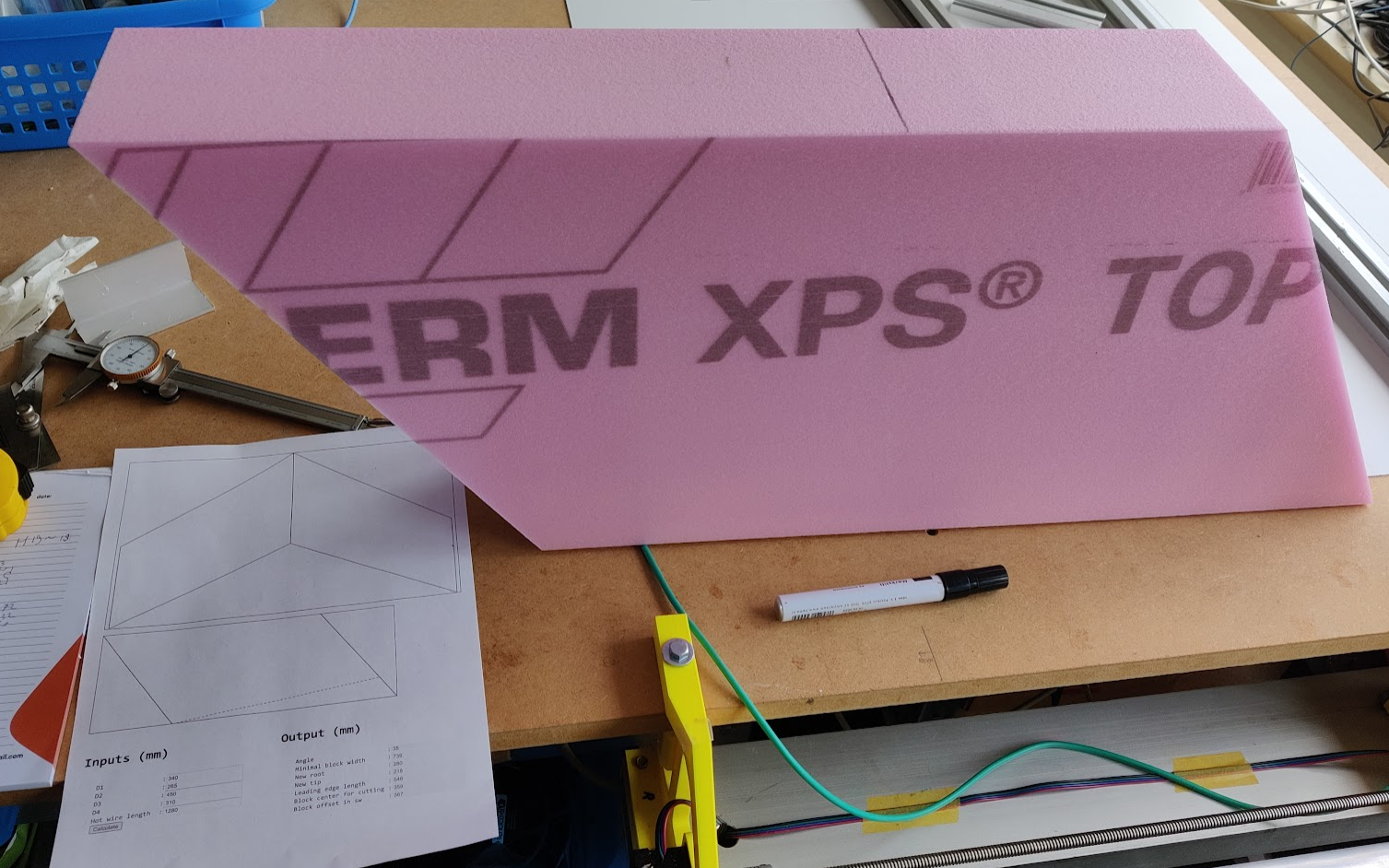

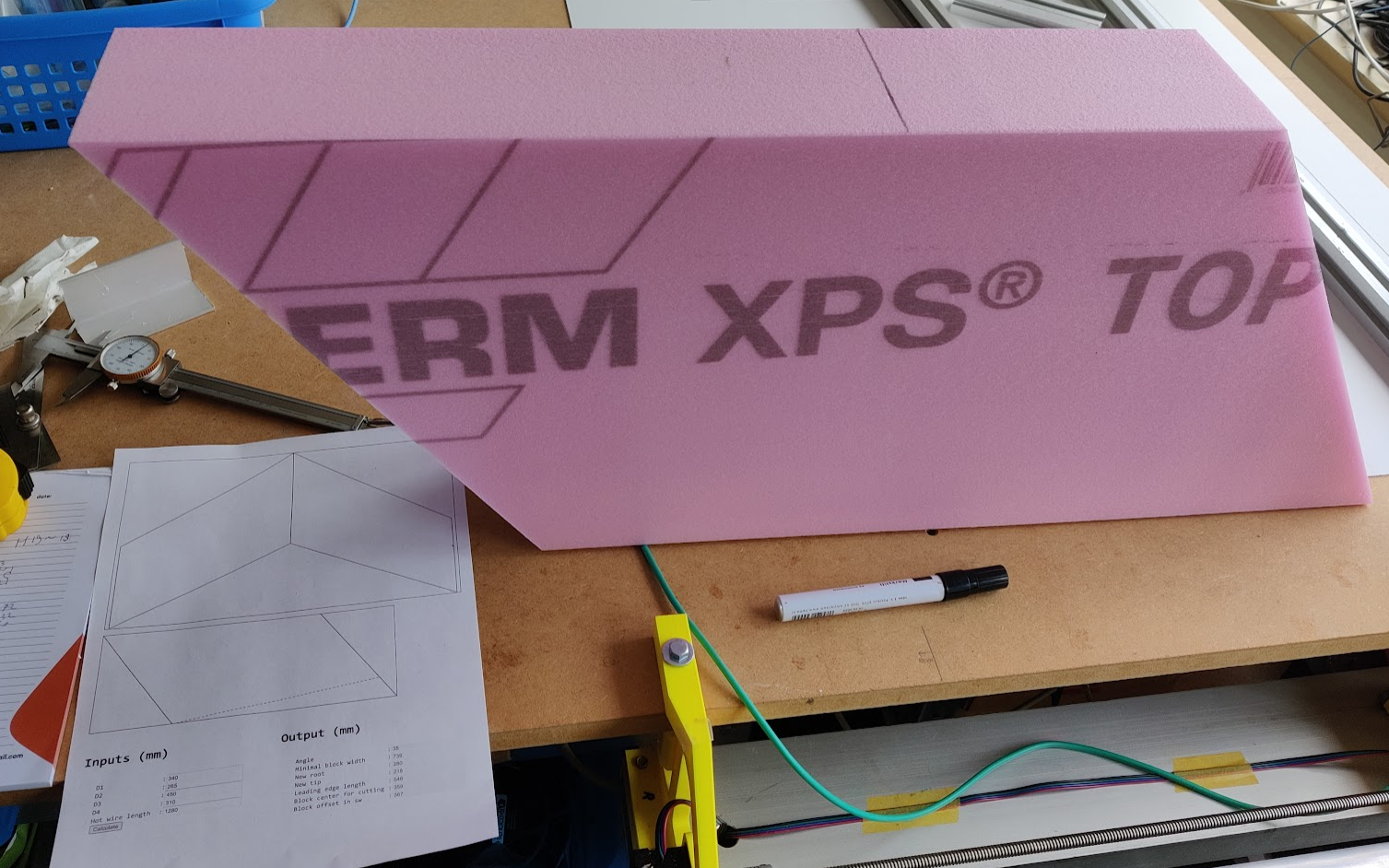

Perspective skews the foto but the left and right side of the block are parallel.

Root is on the left side. Tip right. Calculated center point is marked.(This isn't the center of the block but the calculated center to minimize distorion when cutting the airfoil in an angled block)

Cutting a wing. I have a piece of cardboard with markings for angles and alignment under the block.